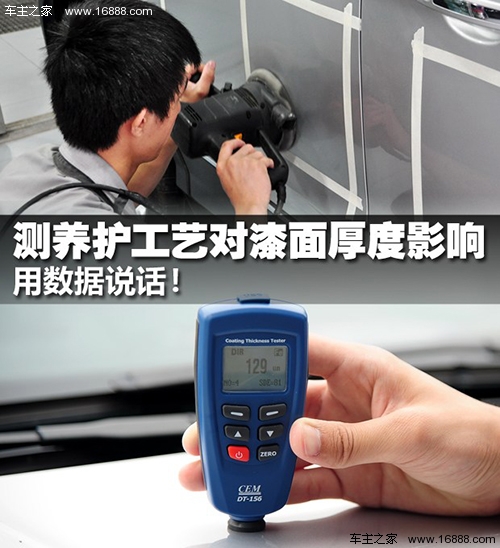

【The owner's family car knowledge】 Today I’m going to talk about a question that many people have paid attention to and discussed before, that is, whether these maintenance processes can really form a thick protective film to change the thickness of the paint.

To this end, we performed a round of actual operations again to see what the actual data was. The purpose of this comparison is to look at two sets of data: one is to look at the change in the thickness of the paint surface after the construction is completed; the other is the thickness of the protection layer after a period of time after the construction is completed.

● Comparison of paint surface thickness before and after 3 kinds of process construction

★ Preparation

In order to accurately compare the effects of the three types of processes on the thickness of the paint, we used the same car for testing. Except for the normal car wash, no other paint maintenance work has been done.

The construction process was carried out in a 3M beauty shop in Beijing. The first step of any paint maintenance is to wash the car in the shop. Our Mavericks paint is still very good, and the paint is very bright after washing.

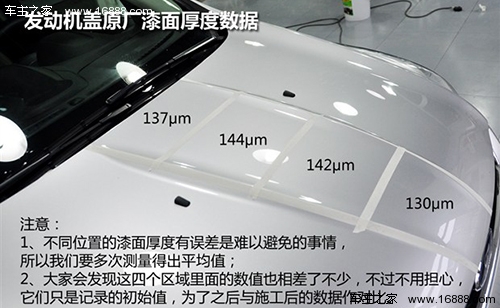

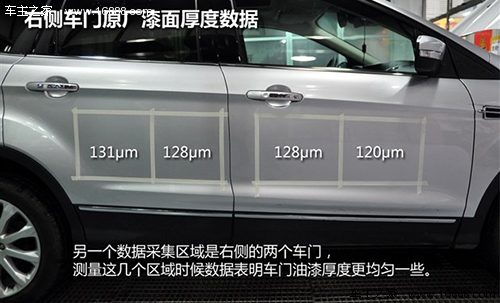

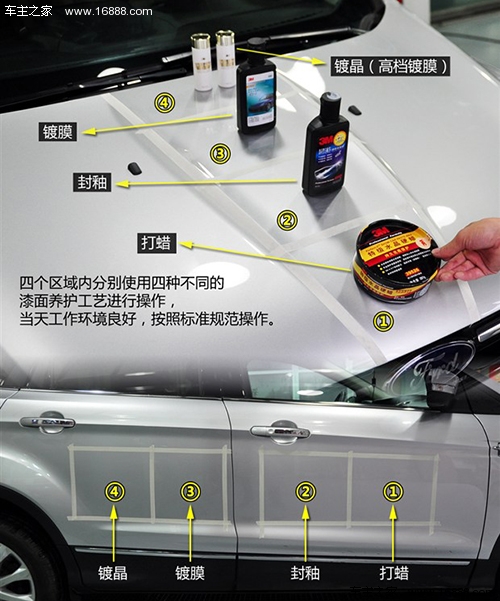

We sampled data on two parts of the car body, one is the engine cover, and the other is the door. The data collected in two places is to avoid possible errors in a single set of data. We have divided and numbered the two parts respectively, corresponding to the four lacquer maintenance processes.

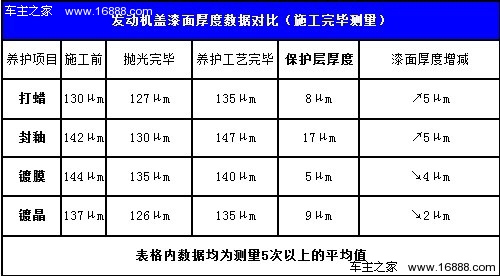

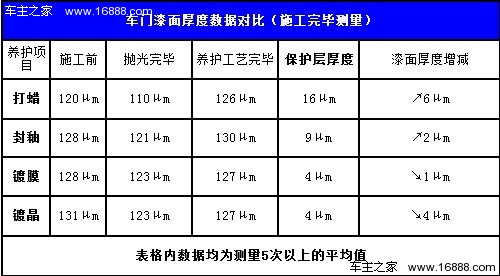

In addition, in order to reduce the error, all the data in the article are the average values obtained after 5 times of multi-point testing in the area. The data unit of the tester is micrometer (μm), and the following is unified as μm.

★ Construction

The four processes implemented are: 1. waxing; 2. glaze sealing; 3. coating; 4. high-end coating (3M brand calls this process crystal plating, in order to distinguish it from the coating, hereinafter collectively referred to as crystal plating).

★ Variation of paint thickness after construction

Let's take a look at the data of the engine cover area after the construction is completed. In addition to the decrease in the thickness of the coating area, the thickness of the waxing, sealing and crystal plating areas has increased, and the waxing and sealing parts The increase in thickness is greater than that of the coating and crystallized areas.

The data of the right door part did not change much, except that the thickness of the manual waxing process was increased by 14μm, the increase and decrease of the other three process areas were all within 4μm.

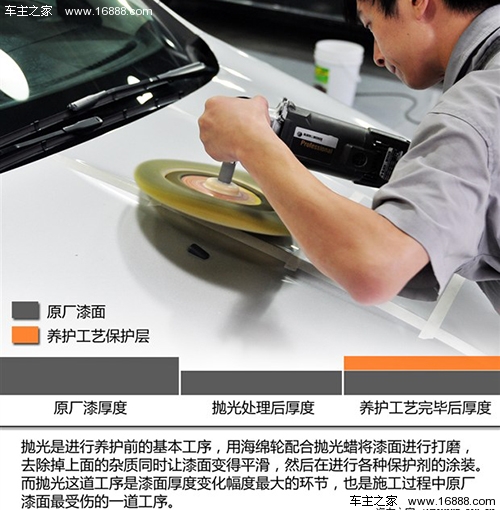

The data collected after the completion of the construction shows that these processes have an impact on the thickness of the paint surface, but it is not absolutely thicker, but also thinner, and this change is not very large. This is because in the construction process, in addition to waxing, it can be directly operated after washing the car (for the accuracy of the experimental data, the polishing treatment was also carried out before the waxing). The processes of glaze sealing, film coating, and crystal plating all need to be performed. The paint surface is degreasing and polishing treatment. The so-called polishing is to make the various curing agents show better results. The paint surface is polished to remove the impurities on the surface and make the paint surface smooth. Then, the paint surface is smoothed. Painting. The polishing process is the link with the largest variation in the thickness of the paint surface, and it is also the process where the original paint surface is the most injured during the construction process. A friend from a car repair shop said to me: "The thickness of the paint is almost consumed if the car is polished for about 7 times...".

For the four curing processes mentioned above, the polishing process is required, which is equivalent to removing a thin layer of paint and adding a thin layer of curing layer. Therefore, the thickness of the paint surface after the construction is changed by two. The results of the superposition of these changes, some are increased a bit, and some are decreased a bit. From the overall results, except for the thickness of the coating area of the engine cover and the coating and crystal area of the right side door, the thickness of the other process areas has increased by 2-6μm. It shows that the paint surface maintenance process is beneficial to the paint surface thickness.

This is the fresh data after construction, and how long the protective layer can support is more of a concern. Let’s take a look at the data collected again one month after construction.

Email:

Email: