Preface

This week, I will bring you the reasons why the clamped workpiece is separated from the gold end face of the fixture seat, the fixture program for the main arm of the auto parts, and the processing technology of the 2-axis parts.

Problem 1: The reason why the clamped workpiece is separated from the gold end face of the fixture seat

Specific working conditions:The lathe fixture uses a translational chuck to clamp the outer circle and end surface of the car. When the workpiece is manually attached to the gold end surface of the fixture seat, the clamped workpiece will be separated from the gold surface, and the length of the clamp is about 5 mm and the diameter of the circle is 48.

Thinking enlightenment:

A:The slider gap is large

B:Try to reduce the clamping force of the chuck. The jaws deformed after clamping the workpiece and opened up. The claw is not rigid enough, and the weak part deforms in the direction of the arrow, clamping the workpiece.

C:The red part is filled and it may be improved.

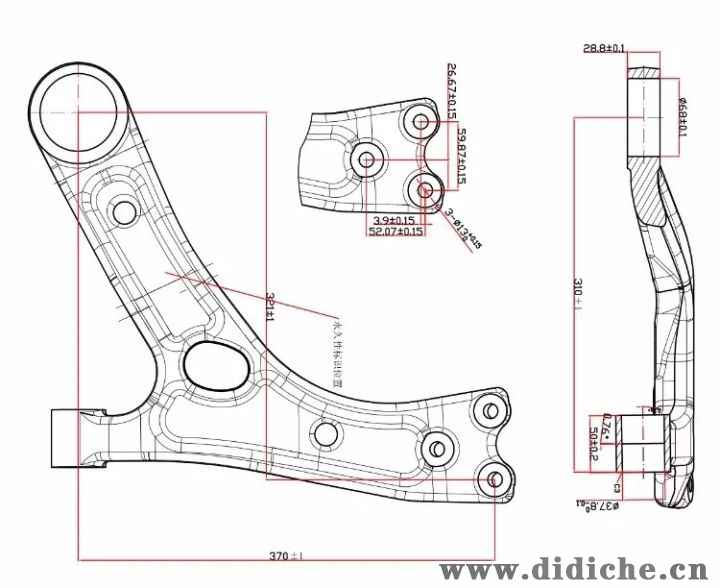

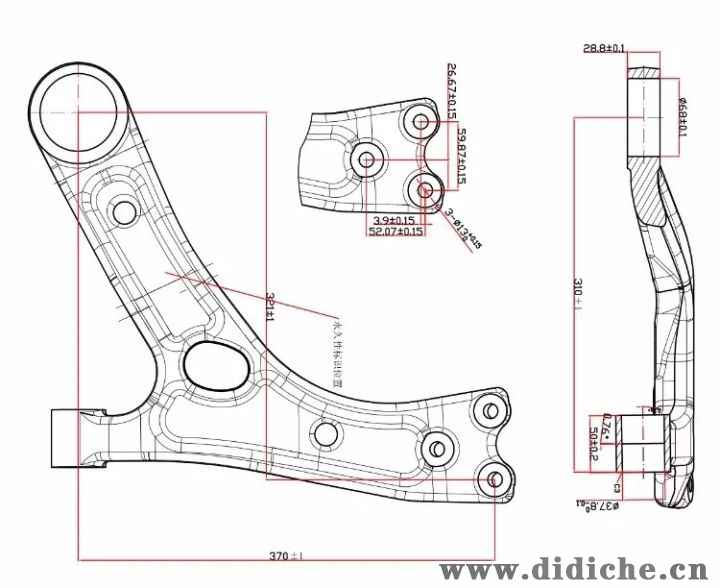

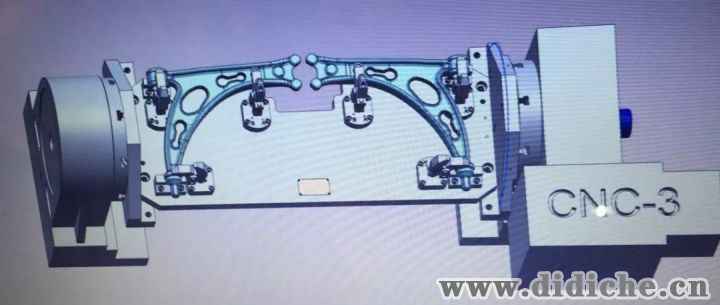

Problem two:Auto partsMain arm fixture program

Specific working conditions:There are several small holes that can't be processed directly by turning directly, and they are not in the same direction.

Thinking enlightenment:

A:The red part is placed in the machining center with four-axis one-time processing, and the yellow part is used as a drilling tooling. The curved tool on the vertical bed is directly connected to the hole and the surface is formed.

Problem three: 2-axis machine parts processing technology

Specific working conditions:Material 45# steel, equipment is Doosan Inclined Rail Car, 2-axle machine. I want to process this part on a lathe, but I don’t want to do it immediately.

Thinking enlightenment:

A:Car 3 times, first make the threaded hole, so that the burr is small.

If you have a corresponding solution to the above problem, you may wish to leave a message below. If you feel you haven't watched it yet, you can enter the technical help section of Jigman's official website.

Email:

Email: