Differentiation of hydraulic pipe fittings typesThere are two types: hose joints and hard pipe joints.

Each of these two categories can be divided into several subcategories:

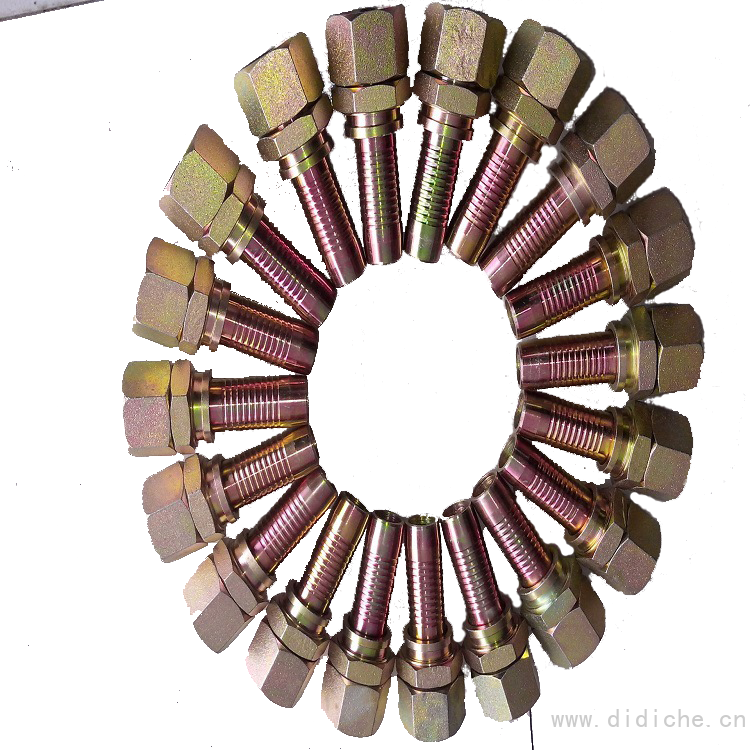

1) Hose joints are divided into integrated hose joints, buckle hose joints and internal locking hose joints.

Hose connector, detachable hose connector, etc.

2) Hard pipe joints are also called transition joints, which are divided into DIN ferrules and metric threaded joints.

British threaded joints, American threaded joints, welding flanges, mining joints, etc.

There are several threading conventions for hydraulic fittings.

Type A is flat head.

Type H is an enlarged 26 degree angle inside.

O type is flat head and can put O ring

Type C is the 60-degree angle of the inner cone, commonly known as concave, also known as expansion.

Type D is the outer ball head.

Specializing in the production of various specifications of rubber hose joints (metric, imperial, American), oversized joints (metric, imperial, American), coal mine joints, engineering machinery joints, welded pipe joints, jacket joints, minesAccessories, Hydraulic joints, oil union, various machining parts. S special joints, various non-standard products can be produced according to user needs

The factory has professional product planners and production management teams, skilled operators and experienced sales elites to ensure that we provide customers with high-quality products and efficient services. At the same time, relying on modern technology, strict quality management network and advanced production technology to ensure product quality, has won the customer's commitment.

The factory will sincerely communicate and cooperate with customers and friends with first-class planning, first-class products, and first-class benefits. We sincerely hope that users can provide valuable opinions.

Warmly welcome new and old users to patronize, welcome people of insight at home and abroad to cooperate and seek common development!

Leak-proofing of high-pressure rubber pipe joints

In the hydraulic system, whether it is a metal pipe joint or a hose joint, there is a simple leakage problem. For jacketed pipe joints, due to greater external force or impact, most of the joints leak, resulting in loosening of the jacket or deformation of the pipe end. At this time, check whether the jacket is out of round, whether the edge is defective, whether the pipe end is defective, whether the jacket nut is tight, etc., and at the same time, eliminate the external pressure of the pipe. For flared pipe joints, due to over-flaring, poor quality or repeated disassembly, most of them leaked, resulting in flaring deformation or cracks. At this point, the front end can be truncated and flattened from scratch. If the male cone and female cone are used for pressure sealing, the leakage is mainly caused by the damage of the two cones. The cone can be sanded. In some cases, the "" ring is sealed by the end face or outer diameter.

Analysis on the Causes of the Leakage of the High Pressure Hose Joint

There are several reasons for the leakage of high-pressure rubber pipe joints: the "ring" is aging or deformed to cause leakage; the "ring" is insufficient to cause uneven pressure or the "ring" is cut when connecting two planes to form a leak; the "ring" is incomplete Lead to lack of elasticity and lead to leakage. Forming; the seal ring groove is too deep and formed. Leak. In order to reduce the depth of the groove, it is necessary to select a "" ring with the same outer diameter and a thicker section from the scratch, or cut or grind the sealing surface with a groove, so that the "" ring has sufficient elastic deformation (shrinkage should generally be medium At N 0.35-0.65 mm).For the use of oil-resistant rubber sheet, felt, mild steel cardboard, combinationGasketOr leakage at the joints of the sealant, no matter what kind of raw material, check the seals for damage, deformation, aging and roughness, and then take corresponding measures.

Problems with high-pressure hose joints

(1) In the process of moving or stopping, the hose should not be excessively bent, nor should it be bent at the root, at least from 1.5 times the diameter;

(2) When the hose is moved to the extreme position, it should not be too tight, it should be relatively loose.

(3) Try to prevent the change and deformation of the hose;

(4) Rubber hoses should be kept away from heat radiating parts as much as possible, and heat shields should be used when necessary.

(5) The external damage of the hose should be prevented, such as long-term conflict with the appearance of parts in operation.

(6) When the hose is deformed due to overheating due to its own weight, a support shall be provided.

Email:

Email: